Trend article

Dairy packaging in the US: the rise of IML

More and more US dairy brands opt for IML to decorate their packaging. And for good reason!

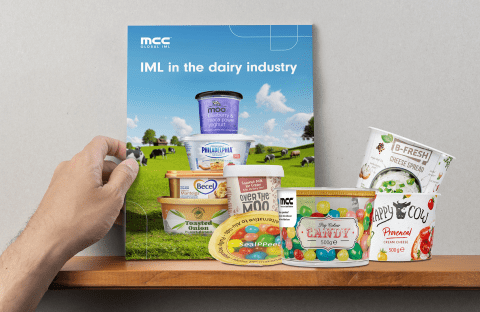

Get inspired by our Dairy Inspiration Box

Discover all the possibilities of IML labels for the Dairy Packaging market

Brands switching from another label technology to IML

Our year-long experience in the IML market, and more recently in IML for dairy packaging, shows that the process of switching to IML from another label technology roughly is a 3-stage journey.

Mimicking

At first, brands will adopt IML and use it to mimic the ‘old’ label solution, like direct printing. No extra features are explored yet and the artwork mainly remains the same, waiting for the consumer’s reaction to the updated packaging.

Optimizing

The second stage is when they start optimizing the artwork. Offset printing allows for much higher quality, so the design can be more detailed, the number of colors can be adjusted, … These are all elements that help the artwork to come to life allowing high quality images.

Premiumizing

Going for premiumization is the final step. This is the part where the look and feel elements come to play and where the artwork gets a make-over in order to make an impact on shelf. Think: certain design or brand elements that get highlighted using a metallic finish, or a spot varnish to create texture.

Other options are adding interactive properties, allowing not only for consumer engagement (via AR, gamification, etc.) but also have their worth in other parts of the supply chain. Digital Watermarks for example, used in Interactive IML, can be used for track & tracing, anti-mixing at the production lines, all the way through POS (interaction), consumer usability (faster check out), and end of use (facilitating the sorting process).

IML as the sustainable choice for dairy packaging

As mentioned higher in this article, sustainability is one of the reasons for brand owners to switch to IML decorated packaging.

Adding properties like barrier protection can increase the shelf life of dairy products, helping to prevent food waste. Looking to downsize the amount of plastic in your packaging? IML also allows for light weighting.

A polypropylene tub decorated with an IML label, is 100% made of the same material (mono-material). This significantly facilitates the sorting process for the consumer at home, as he no longer needs to separate the different materials. But also at the recycler’s level, a mono-material packaging gets recycled more accurately compared to hybrid packaging.

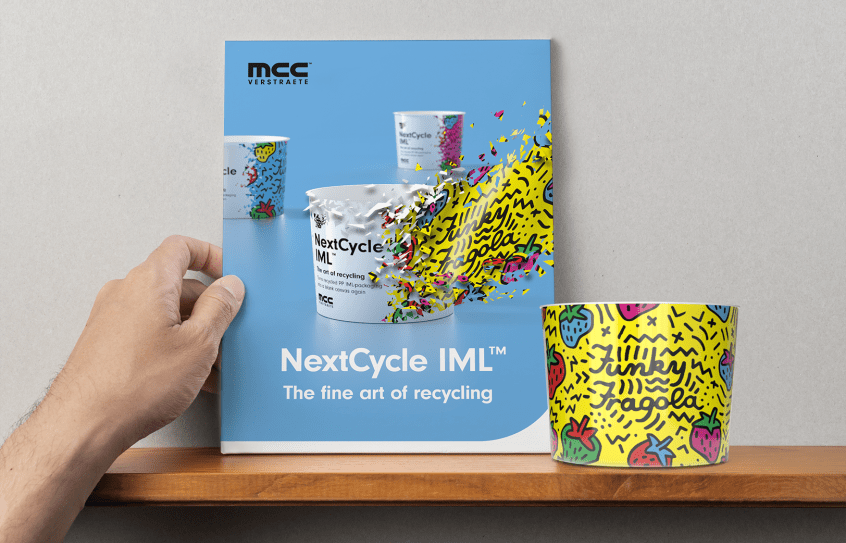

The newest label technologies like NextCycle IMLTM are specifically designed for the mechanical recycling process, paving the way for high-purity rPP. We’re dreaming of a world where NextCycle IMLTM packaging gets combined with SealPPeel PP die-cut lidding. This would allow for even more accurate sorting and recycling, as the combination of a PP tub and a PP lid really is a 100% mono-material pack.

Key takeaways

- The dairy packaging market centers around reliability

- IML offers options for customization and premiumization

- Mono-material IML-packaging facilitates the sorting and recycling process