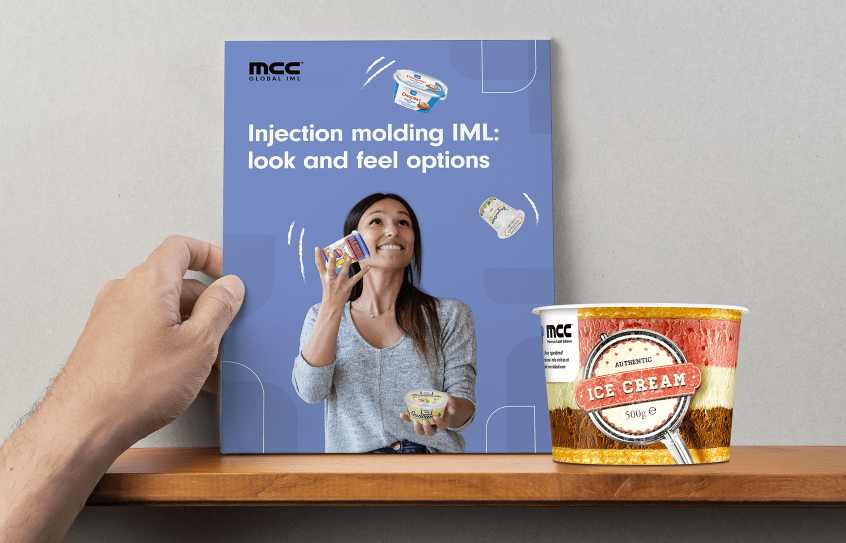

During the injection molding process an amount of heated liquid mass is injected under high pressure into a mold. The mass cools off and solidifies in the shape of the mold. Injection molding is used for all kinds of containers, such as butter tubs and yogurt pots.

What is injection molding IML?

IML for injection molding means that the decoration of the product takes place in the mold. An IML label is inserted into the mold. During the injection process, the injected molten polymer fuses with the in mold label. The end result is a decorated packaging part, produced in one step.

Who do you need?

To perform in mold labeling during the injection molding process, the involvement of the following partners is required:

- the injection molding machine partner

- the IML automation partner

- the mold maker

- the resin supplier

- the IML label specialist