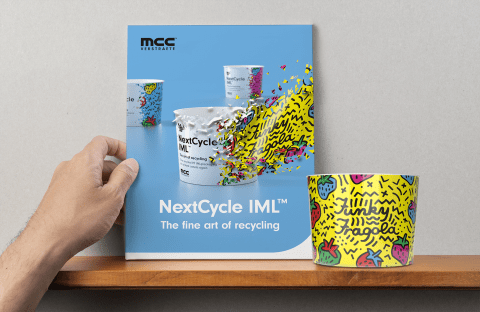

NextCycle IML™

Driving circular IML packaging

NextCycle IML™ - The fine art of recycling

NextCycle IML™ is a revolutionary in mold labeling (IML) technology developed to release from the container during mechanical recycling. The auto-releasable label enables a fully decorated IML packaging to be mechanically recycled into high-purity recyclates, without impact of the label on the recycled material, paving the way for contact-sensitive recyclates.

How NextCycle IML™ works

PPWR ready

According to PPWR requirements, by 2030 plastic (non-contact sensitive) packaging will need to consists of up to 35% PCR content.

NextCycle IML™ technology helps tackle the current rPP bottleneck by enabling recyclers to provide large quantities of high-quality rPP to meet the growing demand.

RecyClass approved technology

For both colored, white and transparent polypropylene packaging as well as HDPE, NextCycle IML™ has received RecyClass approval, confirming its full compatibility with the European rigid PP and HDPE recycling streams.

Take part in shaping the future of plastic packaging!

Discover NextCycle IML™

The NextCycle IML™ product portfolio

This groundbreaking in-mold label technology is a drop-in solutions available for PP, HDPE, PET application in combination with injection molding, thermoforming and injection stretch blow molding (ISBM).

The high-quality printing that you know from standard IML labels, combined with next-level recyclability aspects: with NextCycle IML™ there's no longer a trade-off between shelf appeal and recyclability.

Key take-aways

- Mono-material

- RecyClass approved

- Enables food-grade rPP

- No extra investment from recycler nor converter

- Shelf appeal and recyclability in one

- Lowest possible EPR fees

Be inspired

The NextCycle IML technology allows for the packaging to enter the recycling process without the label. In this case, recycling the JOZO tubes results in white recycled material.