In the food and beverage industry, retort processing is used to extend the shelf life of products while ensuring product safety. It’s a thermal procedure that reduces (pasteurization) or eliminates (sterilization) any harmful microorganisms.

Thermal pasteurization

Thermal pasteurization is a widely adopted technology and uses heat to reduce pathogens and spoilage microorganisms to such a low level that they don't cause disease. The food is subjected to high temperatures for a duration of a few minutes to as much as a few hours. This process is usually carried out under conditions of 100% humidity by immersing the packaging, for example, or by treating it with steam.

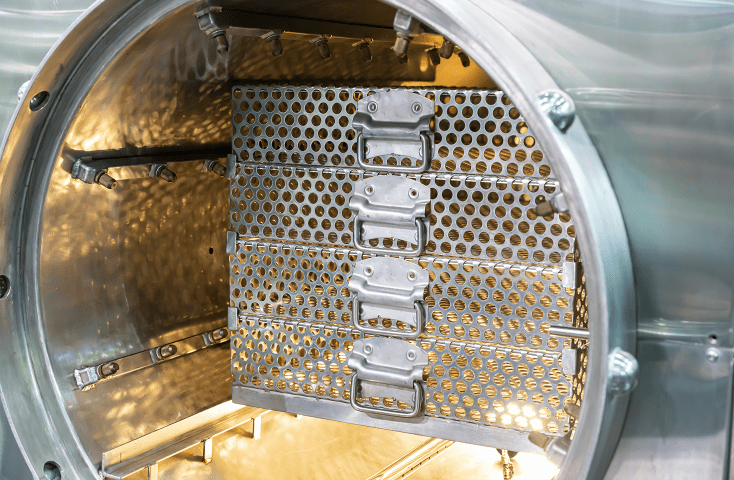

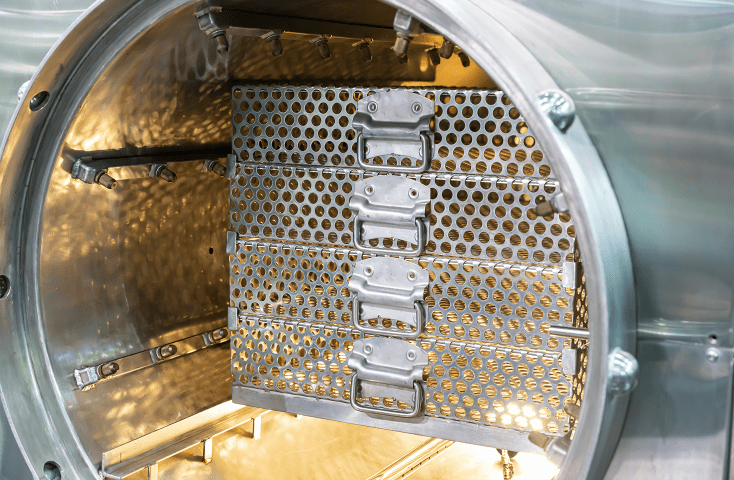

Sterilization

Sterilization is aimed at completely eliminating all microorganisms, using high temperatures and pressure for a longer period of time. Sterilization temperatures can vary from 110°C to 135°C. This can have a significant impact on the product’s properties and packaging.

RetortProof IML

Needless to say, the retort process has an impact on the ink and lacquers of IML labels.

Thanks to a specific combination of inks and a special lacquer, RetortProof IML keeps the inks on the labels from bleeding and fading and prevents damage to the lacquer. RetortProof IML labels retain their quality and appearance, even after the IML packaging containers have been retort processed.