Trend article

Navigating Packaging's Future:

A Conversation on Trends, Innovation, and Sustainability

I anticipate significant advances in refill and reuse strategies that affect all types of materials, including plastic, paper and aluminum.

Paul Jenkins, Founder and Managing Director at ThePackHub

What packaging features do brand owners prioritize to make their products stand out on shelves and create memorable brand experiences?

It has always been important for brands to persuade consumers with their packaging. However in recent times, this battleground has become two-fold — it’s now both ‘on shelf’ and ‘online’. In the online world, customers receive their package days after ordering it. We might call this a "second moment of truth" that influences brand perception after the purchase.

In terms of delivering a pack that impresses the consumer in the ecommerce environment, operators are now under more pressure than ever to reduce their impact on the environment (packaging weight,…) while also providing a sense of luxury (unboxing experience: lacquers & inks, heavier materials, …). Added to this, the scrutiny that brands are now under is immense. Everyone has access to phone cameras and this thrusts brands under a magnifying glass. Every unboxing experience — whether good or bad — can now be shared online and can go viral in a heartbeat.

Other shifts I’ve noticed in packaging include the use of QR codes. They were almost dormant, but the pandemic triggered a renaissance, ushering them into a role of consumer engagement. Brands now wield QR codes as windows into consumer behavior, revealing usage patterns and geographical insights. Finally, on the technological horizon, smart packaging avenues like NFC and RFID will no doubt continue to grow as we move forward into the future.

Want to know more about Interactive IML?

Discover how interactive IML adds value to every stage of the packaging journey

Are there any creative and innovative packaging materials that have caught your attention recently?

The landscape is alight with innovative shifts. Conventional paper substrates are still being used, but hybrid developments with biomaterials accounting for 30% of the content are also common. One example is elephant grass in the Netherlands which provides an alternative to paper, although it’s currently still being tested.

Bamboo is lauded for its rapid growth and carbon-negative properties but of course the ethics of shipping bamboo from one side of the globe to the other merit analysis. It’s one of those materials often associated with greenwashing, so we need to be careful in differentiating true sustainability.

When looking at alternatives to paper based, we need to challenge what is wrong with paper: why should we mix it with a certain amount of other material?

If we look at paper to replace plastics, there are a lot of small trials and pilots going on. One company I know of did switch from plastic to paper, albeit in small runs, meaning that there is still uncertainty around its viability.

Fiber-based materials face formidable barrier challenges, which is something plastic excels at. So there’s a lot of pushback around paper bottles with a plastic lining, as this may mean that the actual paper can’t be recycled. When you dig into these alternatives, some of these initiatives may not be as holy as they were initially made out to be.

Packaging itself is moving more towards mono materials that simplify recycling by using a single plastic type. Brands aim to achieve 100% recyclable packaging, either by changing materials or switching to paper. Projects like Holy Grail 2.0 strive to enhance recycling efficiency through invisible barcodes, yet industry-wide collaboration is essential for success.

The availability of food-grade rPP is one of the biggest challenges for us as a PP in-mold label producer. Do you think PP will survive in the packaging world?

Yes, I think it will survive, but there’s a real challenge. In 2022, the UK introduced a plastic packaging tax on packaging with less than 30% recycled content. But because the supply of rPP’s is so poor, it can sometimes be cheaper to pay the tax than to use recycled content.

I would say the industry is at a crossroads regarding whether chemical or mechanical recycling is the way forward. With mechanical recycling, we have the infrastructure, although it still needs improving in most markets. Chemical recycling is still a bit of an art form, and whether we get a breakthrough that’ll pave the way to further adoption is something worth keeping an eye on. For now, the associated concerns include the cost and environmental impact.

The demand for rPP’s and other plastics will continue to increase as brands strive towards their sustainability goals. In fact, demand is increasing faster than we’re able to recycle, so unless we can find more effective ways of getting quality rPP’s on the market, then it’s going to be hard to meet those increasing needs. Thankfully new solutions are becoming available, such as NextCycle IML which will help to maximize the value of rPP and no doubt help shape a better future.

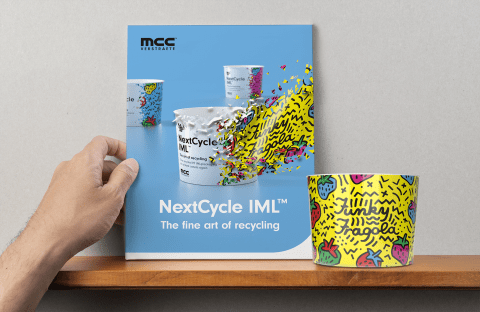

Take part in shaping the future of plastic packaging!

Discover NextCycle IML™

What’s your take on the combination of plastics and cardboard in packaging?

The main challenge posed by the combination is separating the materials for recycling. In the UK market, there's a strong emphasis on combining paper & plastics for dairy products and takeaway, particularly in the on-the-go sandwich market. Sandwiches often require a plastic barrier for protection and this complicates the recycling process. Despite attempts to encourage consumers to separate them, it simply doesn’t work as paper, plastic, and food all end up together.

Looking into your crystal ball, what do you see for the future of the packaging market?

Sustainability will be the primary driver. Looking ahead, it's hard to envision anything but an influx of sustainable packaging ideas. But here's the flip side: as brands and retailers become primarily focused on sustainability goals, other features like easy-open designs and resealability become less common. In this drive towards sustainability, many thoughtful features take a backseat. We're in an era where consumers are questioning excess. It's a different landscape out there and we've got to strike a balance that pleases both the eco-conscious and those who crave convenience.

ABOUT ThePackHub

ThePackHUb is a leading packaging innovation consultancy delivering technical support and project management, events and reports. ThePackHub also manages their market-leading Innovation Zone platform with more than 7,600 packaging initiatives listed. The Innovation Zone is trusted by companies of all sizes. Starting with brand owners, retailers, packaging suppliers and small businesses. Then, expanding to the biggest brands on the planet. Including Amazon, Coca-Cola, Nestle, Kellogg’s, PepsiCo, Kraft-Heinz, Johnson & Johnson (and many, many more). With a vast, searchable, worldwide database, it’s the go-to resource for packaging professionals.