January 26th, 2021

- Sustainability

Simplifying plastic recycling for a sustainable future

Plastic is durable, lightweight and economically efficient. It’s an integral part of modern society. However, the amount of plastic waste currently being generated is cause for concern. Moving to a circular economy will see plastic waste greatly reduced through effective recycling systems.

But achieving this goal requires a shift in focus: plastics need to be designed to be recycled, right from the get-go. This is where HolyGrail 2.0 comes in. It’s a global initiative that encourages manufacturers to switch to packaging with digital watermarks, enabling simpler and more efficient recycling. Orkla, a leading supplier of branded consumer goods in Europe and India, has stepped up to the plate and accepted the challenge.

Orkla’s sustainability goals

"We have ambitious sustainability targets by 2025, including sustainable packaging," explains Pavel Komurka, Packaging Innovation and Sustainability Coordinator at Orkla. "Now is the time for exploration, innovation and overhauling our methods of recycling. Not only do we need to reduce the amount of plastic used in packaging - without generating more food waste - we also need to ensure that plastic packaging is not just theoretically recyclable, but actually being recycled. Bringing in Digimarc barcodes is a huge step towards achieving this goal."

The packaging targets Orkla is aiming to hit in the next five years will see all packaging materials designed with sorting and recycling in mind. Plastic packaging will contain at least 50% recycled components, or components from renewable resources. And it will be designed to be easily identified by automatic sorting processes, ensuring as much material as possible is ultimately recycled.

Accepting the value of plastics

Considering the challenges ahead, there is one burning question: why not just get rid of plastics altogether? When looking at plastics from a waste management perspective, it’s easy to forget how much they have assisted the development of modern society - without plastic, modern life would look very different. Plastic packaging has extended the shelf life of many products, and enabled globalization through the ability to transport foods over long distances. "Some communities and regions have come to view plastics as an enemy to fight, but there’s no rationality behind this. Plastics have greatly aided the human race and improved our living standards," says Komurka. "Our way of life has become dependent on plastics, which is why it’s so important to manage this valuable resource efficiently."

Traffic-light recycling model

To begin the transition to more sustainable packaging, Orkla created an overview of the types of plastics currently being recycled in Europe. They developed a traffic-light model: ‘green’ plastics are already collected and recycled in a traditional recycling system, and ‘red’ plastics are not recyclable. ‘Yellow’ plastics are theoretically recyclable but not actually being recycled. There are various reasons for this: lack of appropriate recycling streams, not having collection systems in place, difficulty sorting the plastics, or not having an existing market for the recycled components.

In identifying ‘yellow’ plastics, Orkla revealed the products with the greatest potential for improved recyclability.

Green light for yellow plastics

For their next step, they worked with the experts at MCC Verstraete to introduce Digimarc barcodes into the packaging of one of their most prominent products. The Interactive IML labels of MCC Verstraete - labels printed with a Digimarc barcode - open the door to new and improved recycling streams. It makes plastics easy to scan, which means automatic sorting is much more accurate.

Our way of life has become dependent on plastics, which is why it’s so important to manage this valuable resource efficiently.

Pavel Komurka, Packaging Innovation and Sustainability Coordinator at Orkla

With Digimarc barcodes, ‘yellow’ plastics are more easily identified, sorted and ultimately, recycled. Thanks to improved recycling streams, more and more ‘yellow’ plastics will be given the green light and merged into the circular economy.

Further interactive features

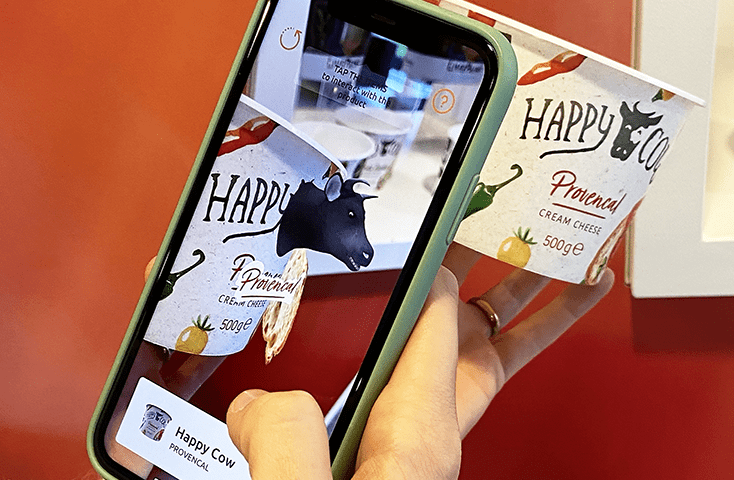

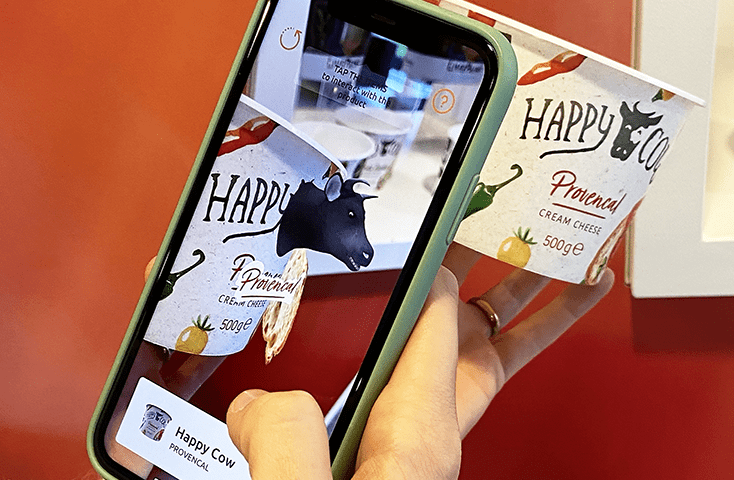

The possible applications for Digimarc barcodes go far beyond just sorting. Scanning technology and augmented reality apps have the potential to provide information in an entertaining way. For Orkla, this is one of the most exciting aspects of this technology.

"We are creating ways to actively engage with consumers," explains Komurka. "With Digimarc, we can alter how people view waste. For example, when a bottle is empty, it becomes unwanted - something to be gotten rid of. Now imagine if, instead of just throwing this away, the consumer could scan the bottle with their smartphone and be shown new possibilities. We could present ideas and provide examples, from reuse options to new products created at the end of a recycling stream. We could make this fun; not only amaze them with the technology and information, but provide a story that they, themselves, are a part of. With Digimarc, we’re able to explore an exciting new world of opportunities."

Future recycling

Orkla is committed to maximising recycling and managing plastic waste responsibly. However, the future is far from set when it comes to recycling being the only option. "Recycling is currently the best method available, but who’s to say this won’t change in the future?" muses Komurka.

"The history of plastic is very short. Could recycling bring new and unforeseen threats? Perhaps the ultimate answer will be something we haven’t even considered yet. Unless we are willing to ask new questions. As times change and new technologies are developed, new options are sure to emerge."

Current status

For now, Orkla is focused on contributing to HolyGrail 2.0 with the implementation and further proliferation of Digimarc barcodes. The first step in this process is to test the waters by introducing interactive IML across a wide range of packaging materials. "We couldn’t be more pleased with the co-operation and service offered by MCC Verstraete. Not only does the new packaging improve recyclability, but it looks fantastic," reflects Komurka.

Following the market release of these products, Orkla will move towards the next phase in optimising recycling: overhauling the waste stream. Nobody may know what that future of plastic looks like just yet, but with Digimarc barcodes and a thirst for innovation, Orkla is paving the way to new possibilities.