June 3rd, 2025

On to the next phase of HolyGrail

HolyGrail2.0, validating digital watermarks as a leverage for intelligent sorting on an industrial scale, was successfully completed in March 2025. Now it’s time for the next stage: HolyGrail 2030 - Circular Packaging.

Technology Readiness Level 9: watermarks ready for market

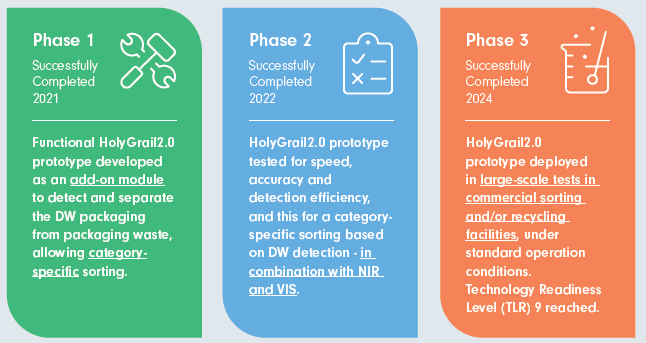

HolyGrail2.0 entailed 3 testing stages. In Phase 3 PET non-food bottles, rigid PP, PP films, rigid PE and PET trays, enhanced with digital watermarks by the participating brand owners and retailers, were placed in the German and Danish market for consumer use, disposal and collection.

Over 100 days, high volumes of materials were sorted:

- detection rates: nearly 56,000 detections per day

- total detections: 5.66 million

- unique SKU’s: 5,949

- detection efficiency: 87.9% to 93.8%

The industrial trials confirmed digital watermarks help to accurately sort post-consumer rigid household packaging, achieving ~90% sorting efficiency even under challenging real-world conditions and single-pass sorting. The technology has reached Technology Readiness Level 9 and is ready for market.

Recycled content to meet PPWR targets

January 2030, the PPWR’s requirements regarding recycled content in plastic packaging will go into force. By estimation, 300 Kton of contact-sensitive rPP is/will be needed to meet these demands (excl. rPP needed for non-contact sensitive applications).

Intelligent sorting and feedstock control are crucial to bridge this gap, with mechanical recycling offering a promising solution to achieve high volumes of contact-sensitive rPP in an affordable way.

Philip Knapen, Marketing Manager Rigid Packaging at Borealis: "Mechanical recycling prevents valuable resources from being incinerated and significantly reduces our carbon footprint. A digital solution is essential to enhance the quality and quantity of recycled feedstock, and digital watermarks are currently the best fit for this purpose, potentially supporting EFSA approvals in the future. Additionally, a digital passport avoids difficult-to-recycle plastics ending up in incineration. Chemical recycling can complement mechanical recycling. Detailed information on the feedstock source is crucial for increasing the yield of pyrolysis production."

Borealis supports the Holy Grail initiative because we believe it will significantly boost the amount of recycled plastics, which is essential to meet the 2030 PPWR requirements for both contact and non-contact polyolefins.

Philip Knapen, Marketing Manager Rigid Packaging at Borealis

Arla Foods chose to join HolyGrail at an early stage and has been instrumental in the project rollout.

Grane Maaløe, Sustainable Packaging lead specialist at Arla Foods: "A few competing technologies are evolving in parallel with digital watermarks, among them AI-powered image recognition. This might seem very easy and hence appealing, but the HolyGrail based sorting is the only solution that can provide us with a proven SKU-based bill of material on the feedstock. The bill of material makes the sorting very accurate and enables contact-sensitive rPP production. We hope that the next project phase can reach a critical mass to create real traction in the recycling market."

Up next: HolyGrail2030

HolyGrail2030 aims to prove the economic viability of smart sorting and reprocessing into high-quality recyclates.

"Advanced sorting technologies, such as digital watermarking, can separate plastic packaging accurately and transform it into higher value secondary base material. This increases the economic viability of the recycled material and represents a unique opportunity for the industry to work together towards creating a more circular future within the EU," says Richard Akkermans, European R&D Packaging and Sustainability Manager at Mondelez.

Landing strips aimed at scaling technology

Over the next 2 years regional landing strips will implement the technology at an industrial scale. The Belgian landing strip will handle flexible PP, the German land strip will cover rigid PP packaging.

At the same time, the HolyGrail2030 participants will challenge the business model to prove that via intelligent sorting extra value can be achieved and drive a circular economy. This data should allow to create more interest and have a fast ramp up towards 2030.

As HolyGrail2030 is technology agnostic, the working groups keep looking and testing alternative technologies for intelligent sorting - including AI and other types of digital watermarks.

Join HolyGrail2030!

Nico Van de Walle, Product & Circular Economy Manager Global IML at MCC: "Intelligent sorting is crucial for achieving food-grade rPP, bridging the availability gap, and meeting recycling targets by 2030. It's time to act, and collaboration is key. Join HolyGrail2030 to make a circular economy for plastic packaging a reality!"

✓ Get first access to high-quality and controlled feedstock

✓ Be in a pole position for access to high-quality (contact-sensitive) rPP

✓ Prepare for PPWR and its recycled content criteria

Contact & membership info via AIM: margherita.trombetti@aim.be