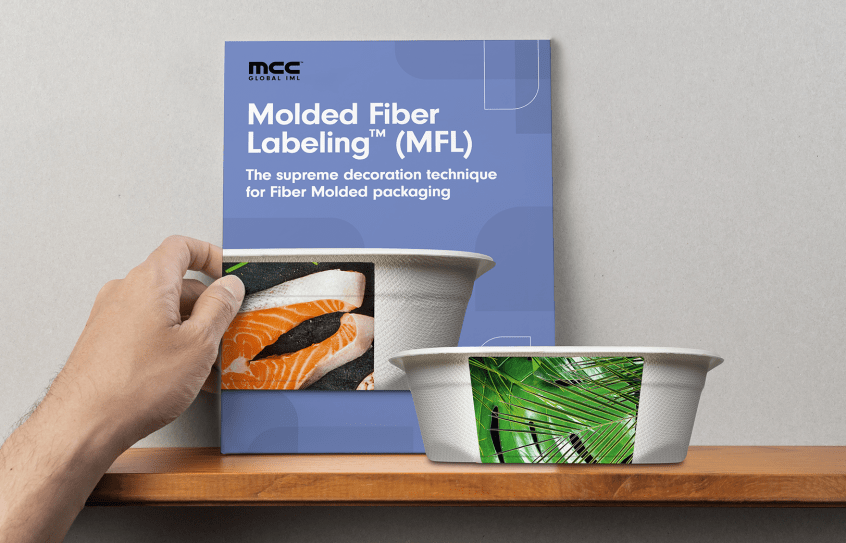

Molded Fiber Labeling™ (MFL)

A unique, sustainable paper label to decorate both wet or dry fiber molded packaging.

Molded fiber packaging is a long existing technology, with primary applications in the field of protective packaging such as egg boxes, trays and electronics. Driven by the development of barrier solutions and the call for fiber based packaging, other packaging markets such as FMCG are now showing a lot of interest and start to adopt this new type of packaging.

As this new type of fiber packaging deserves a sustainable decoration method, MFL™ labels were developed. MFL™ label, a paper label, enables a strong fusion with the fiber molded packaging and is applicable to both dry and wet fiber molding.

To learn more about Molded Fiber Labeling™ watch this video, created by our industrial partner Pagès Group.

MFL™ offers a wide range of unique advantages:

Maximum print quality

The offset printing technique ensures high-resolution images. Besides, it allows all the sides of a container being decorated with one single label.

Strong and hygienic

MFL™ labels resist humidity and big temperature fluctuations and are thus the best solution to decorate Fiber Molded containers. MFL™ labels adhere perfectly to the fiber material, are scratch resistant and are not susceptible to wrinkles.

Looking for a sustainable paper label?

Discover all the ins and outs of Molded Fiber Labeling™

Shorter production time and lower production costs

Depending on the forming technique, whether dry or wet fiber molding, the MFL™ process can be integrated 100% in-line so that the parts are produced and decorated in one single step. Or one can choose to have a sequential MFL™ process where a special MFL™ robot is decorating and inspecting the parts right after the production process.

Mono-material: environmentally-friendly

Molded Fiber Labeling™ saves the environment: the packaging and the glue-free MFL™ label consist of compatible fiber materials and can therefore be fully recycled or composted. Using pre-cut labels allows you to have a waste-free decoration process.

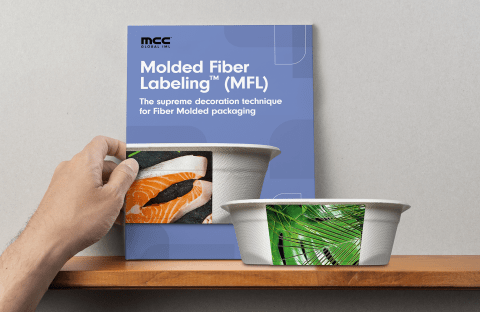

Wide range of look & feel options

Molded fiber packaging can be decorated with different materials, inks, lacquers and cold foil. Use it to your advantage to differentiate your product on shelf!

Quick design changeovers

It only takes a small switch from one label design to another on your MFL™ automation to make a quick changeover. There is almost no production loss during the start-up of a new design.

Flexible supply chain

Next to integrating the MFL™ process in-line, the MFL™ decoration can also be applied off-line. This offers more flexibility within the supply chain: stored fiber packaging can be decorated just before shipment to the brand owner, or it can even be applied in-line with the filling process at the brand owner.