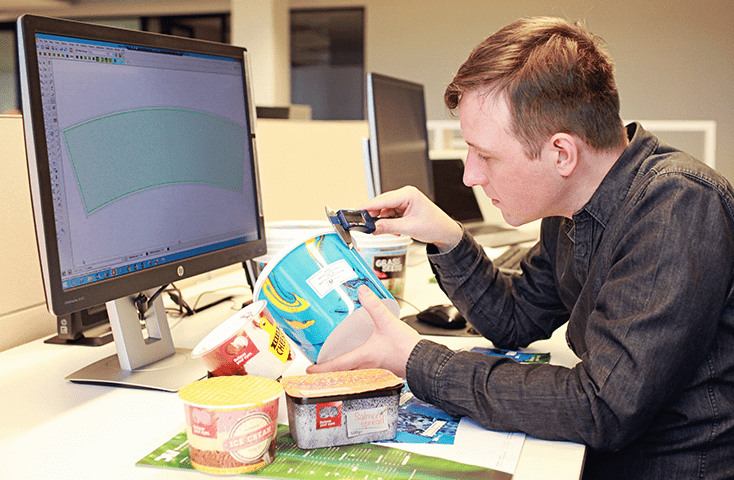

MCC Global IML's tooling service checks the label drawing from a technical point of view, prepares it for further processing, and advises on possible finishing methods.

The tooling team are experts in optimizing the label drawing in order to create a successful IML product. For example, they correct gaps and overlap by making them wider or more narrow. Or they straighten V-shaped seams. Tooling also assists in so called blowby cases.

Next to label optimization, our tooling service manages the tools used in the finishing process. Often these tools are custom-made for your project. Our experts track the wear of tools and replace them if needed, to make sure your labels always enjoy the best quality when being produced. The goal is to maintain the finishing quality of the tools up to standard; whether it’s the first, the second, or the 100th order.