Medical IML

Medical IML

In-mold labeling as a game changer in Medical and Healthcare packaging

The cutting-edge Medical IML process uses medical-grade materials and specialty labels, advanced automation and a quality control system to produce and decorate medical parts.

Thanks to Medical IML, your medical and healthcare packaging benefits advantages such as traceability, risk reduction, clean, efficient & reliable production process, and many more.

Efficiency & Repeatability

- One-step process reducing floor space, internal transport & staff

- Waste reduction compared to other frequently used decoration techniques

- Low cycle time

- Precision, accuracy and control

- Arburg's full-electric Allrounder 520A

- Kebo's high performance IML mold

- Beck Automation's label adjustment head

- Intravis' IML watcher

- In-mold labels by MCC Global IML

Flexibility

- Quick design changeovers

- Adapt & create designs easily

- Functional & decorative label enhancements:

- Barrier properties

- Double sided print

- Matt/Glossy finish

- Digital watermarks

- Serialization & individualization

Cleanliness, Quality & Safety

|

|

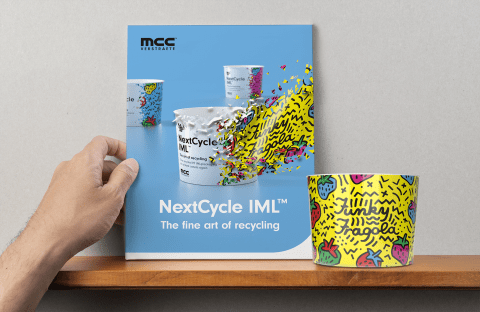

Sustainability

- Glueless

- Mono-material packaging

- CO2 neutral IML production

- NextCycle IML: self-separating during mechanical recycling process

Take part in shaping the future of plastic packaging!

Discover NextCycle IML™

Meet the 5 Medical IML partners: