Trend article

NPE’s top 4 highlights according to our team

Discover the best of IML at NPE2024

After 6 years of waiting, the largest plastics trade show in the Americas returned with a bang! Under the ‘Made for You’ tagline, the fair was the place to be for innovators in packaging, medical, machinery, robotics, etc.

According to our entire Americas team at NPE2024, if you didn’t attend you really missed out. We sent out our team across the 1.1 million square feet of exhibit space and asked them to list the 4 not-to-be-missed highlights. This way, even the non-attendees get to feel the innovative spirit of the fair.

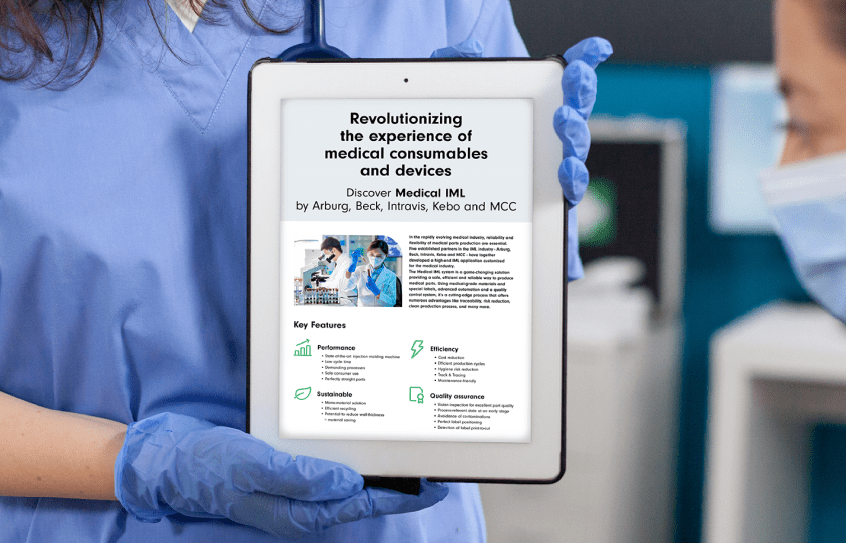

1. Medical IML

From implants and devices to 3D-printing, the fair showcased the innovative use and future of plastics for the medical industry.

“A revolution in the medical sector is looming. The power of injection molding for medical applications is a territory ready to be explored,” says Kim Blondeel, Business Development Manager Medical IML. “This was reflected in the high interest for the Medical IML system we showcased together with our partners Arburg, Kebo, Intravis and Beck Automation.”

“The main benefits to remember? The fact that it’s a mono-material solution for medical applications, with high-precision label placement and 0.2 mm print-to-cut precision, and that it allows for features such as unique coding – very relevant for the medical sector. And let’s not forget the manufacturing is a one-step, quick and clean process.”

2. The value is inside: recycled content

“A top 3 of NPE highlights can’t go without novelties in sustainable packaging,” says Mathieu Nieuwenhuyse, Managing Director MCC Global IML Americas. “Recycled content is getting increased attention – a clear focus of several exhibitors at the fair .”

“Our partner Milacron injected 5GL HDPE pails with co-injection technology live at their booth*. Up to 50% of the core of the pail is made of recycled content. Combined with IML automation and our Matt and High Gloss IML labels, the outcome is a perfect, more sustainable alternative to virgin plastic buckets.”

*System partners: Mold - Sybridge, Automation - Beck Automation, Hot Runner - Mold Masters, Vision system – INTRAVIS

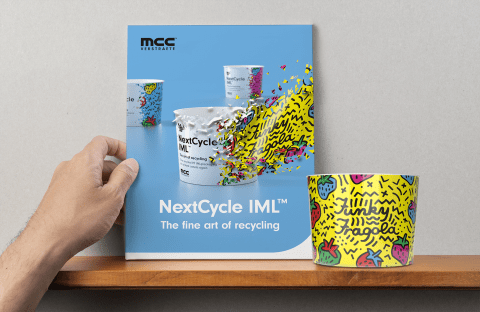

3. Designed for circularity

New to this edition of NPE was the Sustainability Hub highlighting the ongoing industry efforts to promote a more sustainable plastics economy. As pioneers in sustainable IML, we couldn’t miss this opportunity to showcase NextCycle IML™, our label solution for recyclable, even circular PP packaging.

Next to that, our Global Product and Circular Economy Manager Nico Van de Walle engaged in a Fireside Chat with APR’s Scott Trenor on how to upgrade your rigid IML packaging from recyclable to circular, paving the way for circular, potentially even food-grade mechanically recycled rPP.

“Sustainable packaging design is the future – you couldn’t miss it at NPE’s newly installed Sustainability Hub. Leaning into that, the lightweight, NextCycle IML™ decorated containers produced at Arburg’s booth* using the injection compression molding process, are a textbook example of design for circularity,” says Nico Van de Walle.

“By lightweighting the container, less virgin plastic is used. Win #1. By choosing for polypropylene for the container as well as the label, the packaging becomes mono-material. Win #2. The third win hides in the decoration technology: NextCycle IML™ labels automatically detach from the container during the mechanical recycling process, resulting in high-purity recycled PP. The future of PP packaging, if you ask me!” Nico concludes.

*system partners: Mold & Automation – Brink Moulds & Automation, Resin: Borealis, Hot runner: Männer

Take part in shaping the future of plastic packaging!

Discover NextCycle IML™

4. Thin-walled PET packaging

Another eyecatcher in the ‘recyclable packaging’ category was the thin-wall PET system by Netstal*. The Swiss injection molding machine manufacturer showcased an ultra-transparent 100% PET cup, optimized for recycling with PET IML decoration. The empty transparent cups can be processed into high-quality recyclates together with empty PET bottles.

“In Europe in 2022, half of all PET bottles placed in the market were recycled. However, for all types of PET packaging, the rate is only 35% (source: Statista). Due to its good recyclability and the established recycling systems across countries, the idea of using PET for thin-walled packaging AND making it specifically recyclable, has high potential”, says Evie Vens, Partner and Brand Owner Manager at MCC’s IML business unit.

*System partners: Mold & Automation: StackTeck, Vision System: IMD Vista, Resin: Eastman