Innovation by MCC Global IML

Why does Polyoak swear by MCC Global IML as IML partner? “In one word: innovation! In its choice of materials, efficiency of the production process and the advanced printing and finishing processes. The result is a quality product and first-class service!”

From self-adhesive label to IML

In the past there were decorated self-adhesive labels on the top of the lid and on the base of the popular Melrose Wedges tubs. Polyoak purchased the labels from an external supplier, stuck them on the packaging and supplied everything together to the producer. An intensive process that the producer wanted to simplify. Moreover, they were looking for a total branding and packaging solution. The objective: greater visibility of the Melrose brand on the shelves. The solution: IML.

- Shorter production time as the label is moulded into the packaging.

- Endless branding possibilities as packaging and label are one.

- Lower production costs as the process is less labour intensive.

- Excellent printing quality thanks to offset printing.

- Both the packaging and the IML label are fully recyclable.

- A bigger label which allows a more accurate fit around the openings that let oxygen through.

Cheese and packaging with holes

The ready-for-use IML labels for the Melrose Wedges are molded into the brand-new lid and tub. There are even breathing holes for the cheese as the product is hot filled, which is vital for the shelf-life of this product. This makes this kind of label unique – certainly in Africa! Melrose Wedges’ new IML packaging also stands out with its stylish details. Guaranteed strong presence on the shelves in the shop!

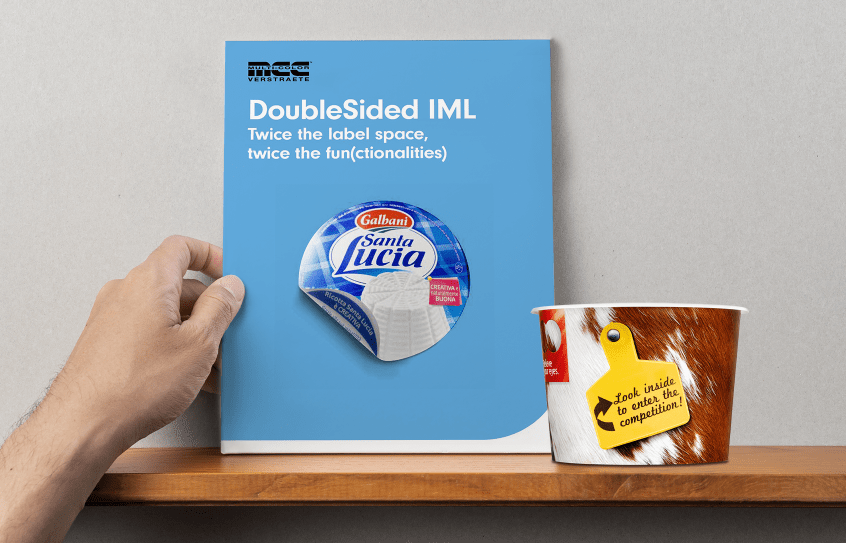

DoubleSided IML: twice as much space

The Melrose Wedges have DoubleSided IML packaging. This means: printed on both sides. The perfect solution to comply with new South African legislation which makes it obligatory for producers to put more information on labels. With DoubleSided IML labels you have twice as much printing space as compared with a traditional label.